Screw equipment manufacturers control production

来源:www.spiralweldedtubemill.com 发表时间:2017-11-01

Spiral pipe equipment manufacturers to control the first is to improve the plastic resistance of steel, improve the cleanliness of molten steel to reduce the harmful mixed, improve the overall quality of steel. In the production process to choose a reasonable cooling criteria to prevent the internal cracks, from a variety of ways to improve the quality of steel.

Spiral steel pipe in the production process reasonable control of heating temperature, by measuring the thermoplastic curve, select the best heating temperature. Tube heating should also pay attention to have to meet the insulation time to drop the deformation resistance and progress 45 # structure thick-walled spiral pipe resistance.

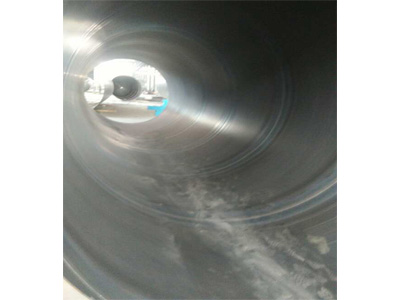

The production process of the spiral steel pipe requires more procedures. The final step is to decrease the roll speed. The roll speed is the key parameter of the piercing process. There is a critical roll speed at the beginning of the roll speed from low to high. When the roll speed is low, the tube is simply formed into the cavity; when the roll speed is high, the tube and the 45 # structure spiral steel pipe simply constitute the drawback. In order to eliminate the defects of the tube and the 45 # structure of the spiral steel pipe, the roll speed should be reduced to the beginning of the stratum below the critical roll speed