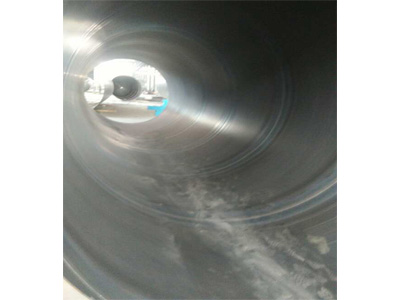

What if the screw welded pipe parts are damaged

来源:www.spiralweldedtubemill.com 发表时间:2019-10-28

Maintenance of spiral welded pipe equipment in accordance with the corresponding maintenance specifications for regular maintenance, even if the working state is good, also need to be on the welded pipe unit comprehensive maintenance care, fundamentally prevent mechanical failure, to ensure the smooth production.

During the maintenance of spiral welded pipe equipment, parts found to be severely worn should be replaced. The machine is regularly maintained and maintained by professional maintenance personnel, such as lubricating oil. Finally, good quality anti-rust oil should be provided on the slide side to prevent oxidation and rust of the equipment, especially in the case of long-term idle. Do a good job of maintenance work, for the normal operation of welded pipe equipment is very good, but also can produce smoothly.

In the daily maintenance work, an important point is careful, no matter for the whole operation of spiral welded pipe equipment, or for the replacement of each part of the parts, regularly check the wear of the parts, especially when the workload is large, pay more attention to these parts, in order to prevent wear seriously affect the production process. If the manufacturer of welded pipe sets wants to reduce the wear of parts as much as possible without affecting the production, they can add lubricating oil to the machine regularly, which is also one of the methods to reduce the wear.

For spiral welded pipe equipment, always check the oil level on the tank, oil level should not be lower than the specified value. When the oil filter is blocked by dirt, it should be replaced in time. When the crude oil filter is blocked, it should be cleaned in time, once every 3 months. To fill the oil tank, it must be filtered. The oil should not be mixed with water, rust, metal chips, fiber and other impurities.