Thick-walled spiral steel pipe production process

来源:www.spiralweldedtubemill.com 发表时间:2017-12-16

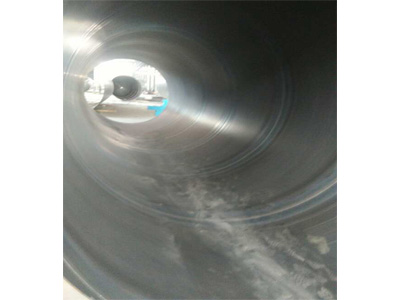

Thick-walled spiral steel pipe production process

1. Spiral steel pipe spiral pipe before the use of advanced production process of double-sided submerged arc welding can be achieved in the best location of the welding, not prone to wrong side, welding partial and impermeable defects, easy to control the welding quality and location. Spiral steel pipe using a special welding process, welding can be achieved at the best location, without any error defects, to ensure the continuity of the spiral steel pipe, the quality is well guaranteed.

Spiral steel pipe forming spiral steel pipe forming process, the plate to be deformed evenly, the residual stress is small, the surface do not have scratches, so the choice of the production of spiral steel pipe to be careful, the surface should be uniform without scratches. Processed spiral pipe in the diameter and thickness of the size range specifications have greater flexibility, especially in the production of high-grade steel pipe, especially small and medium-sized thick-walled pipe, there are other advantages can not be compared to meet Users in the spiral pipe specifications more requirements.