Longitudinal welded pipe quality inspection

来源:www.spiralweldedtubemill.com 发表时间:2017-12-23

Longitudinal welded pipe equipment quality inspection which

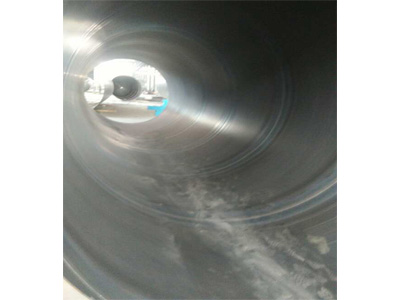

Longitudinal welded steel pipe is a high-frequency welding unit will be a certain size of strip strip rolled into a round tube and straight seam welded steel tube. The shape of the steel pipe can be round or square or irregular depending on the sizing after welding. Spiral welded pipe equipment manufacturers tell you straight seam welded pipe quality inspection of the four methods:

1, the penetration test is the use of certain liquid permeability and other physical characteristics to detect and display defects, including color inspection and fluorescent test two, can be used to check the ferromagnetic and non-ferromagnetic surface defects.

2, the magnetic force test is the use of magnetic field ferromagnetic Q235B Longitudinal Welded Tube produced by the leakage to find defects. By measuring the different methods of magnetic flux leakage can be divided into magnetic powder method, magnetic induction and magnetic recording method, of which the most widely used magnetic powder method.

3, ray inspection is the use of ray-penetrating substances and attenuation in the material properties to detect defects in a detection method. Mainly used to test Q235B Longitudinal Weld internal cracks, incomplete penetration, porosity, slag and other defects.

4, ultrasonic flaw detection, ultrasonic testing of metal defects can be used. Ultrasound can test any weldment material, any part of the defect, and can more sensitive to find the defect location, but the nature of the defect, shape and size more difficult to determine.