Spiral classification criteria and characteristics

来源:www.spiralweldedtubemill.com 发表时间:2018-01-21

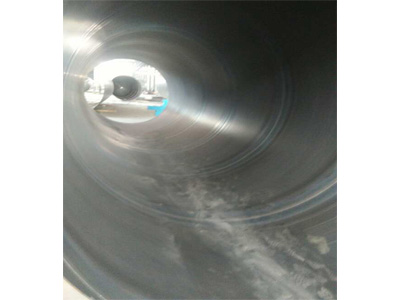

Spiral pipe equipment features: straight seam welded pipe production process is simple, high production efficiency, low cost and rapid development. The strength of spiral pipe production equipment is generally higher than that of straight seam welded pipe. The pipe with larger diameter can be produced with narrower billets. The same width of billets can also be used to produce pipe with different diameters. Spiral Pipe Production Equipment But with the same length of straight seam pipe weld seam length increased by 30 ~ 100% and the production rate is lower. Therefore, the smaller diameter welded pipe are mostly used for large-diameter straight seam welded pipe are mostly used spiral pipe production equipment.

Spiral pipe production equipment and their standard classification: Pressure transmission fluid spiral submerged arc welded pipe (SY5036-83) is mainly used for transporting oil and gas pipelines; pressure fluid delivery spiral seam high frequency welded steel pipe (SY5038-83 ) High-frequency lap welding of welded high-frequency welded steel pipe for pressure fluid delivery. Strong pressure steel plastic easy to weld and processing molding; general low pressure fluid delivery with spiral submerged arc welded pipe (SY5037-83) using double-sided automatic submerged arc welding or single-welded for water, gas, air And steam and other general low pressure fluid delivery with submerged arc welded pipe Now common standards for spiral pipe are generally divided into: SY / T5037-2000 (Department standard, also known as ordinary fluid transmission pipe with spiral submerged arc welded pipe), GB / T9711. 1-1997 (GB, also called oil and gas industry delivery pipe first technical conditions: A grade steel), API-5L (American Petroleum Institute, also called pipeline steel), SY / T5040-92 Arc welding pipe)