Spiral welded pipe unit test sequence

来源:www.spiralweldedtubemill.com 发表时间:2018-01-28

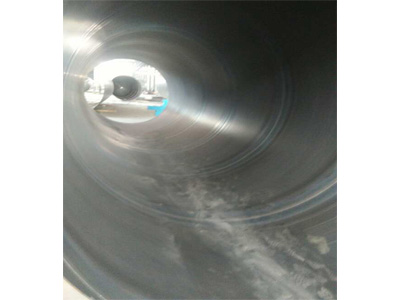

Spiral welded pipe unit test sequence

1, motor and hydraulic motor idling test, check the direction of rotation is correct.

2, stand-alone test run time of 2 hours.

3, gear box gear smooth, normal sound, good lubrication, no oil leakage phenomenon.

4, leveling roller, delivery roller rotation is normal, there may be no movement phenomenon.

5, test the hydraulic system cylinder and pipe joints may not have oil leakage.

6, process operation and description:

6.1 Process Description:

Unwinding → unwinding → leveling → manual vertical roller → butt welding → manual vertical roller → delivery → bending guide plate → forming → welding → output → cutting → dialing

6.2 Operating Instructions:

Strip with the cable from the crane, hanging on the roll car lifting frame, off the hook. Lateral mobile car, the coil into the uncoiler cone. Uncoiler cone cylinder up tight coil. The car lifts down and returns to its original position. Tighten the coil after the coil. Press roller pressure, pressure in the upper part of the strip, shall not loose the coil. Cone and roller rotate simultaneously (jog). Turn the strip head to the unwinding position. Feed device blade extended. Cone head and the pressure roller rotation, the strip rolled tongue smoothly into the feed pinch leveler. (The reduction of the leveling roller is pre-adjusted according to the plate thickness) The uncoiler is disengaged, the micro brake is adjusted, and the pressure roller is lifted. Cutting head and tail butt welding, butt welding car in the cylinder retracted position, the tail cut, the car reached 700mm, cut the head, pinch lead leveling leveler head will be sent to the welding station position, Carry out population welding. The delivery machine will be after welding the strip through the bending plate into the molding machine, forming the outer pipe welding, through the rear axle output bracket, idler output, cut into length, by dialing device dial Out