Spiral welded pipe production equipment protection

来源:www.spiralweldedtubemill.com 发表时间:2018-02-08

1, pickling. Ordinary use of chemical and electrolytic pickling two ways to do, pipeline corrosion only chemical pickling, you can remove the scale, rust, the old coating, and sometimes it can be used as sandblasting rust reprocessing. Although chemical cleaning can make the appearance of the inevitable cleanliness and roughness, but its anchor pattern shallow, and easy to pollute the situation.

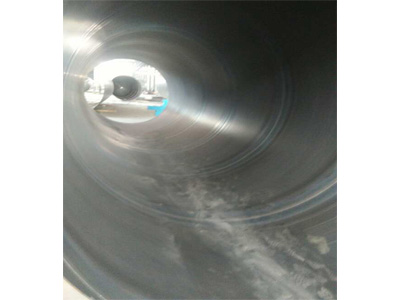

2, spray rust. Spraying rust is driven by high-power motor blades spray high-speed twisting, grit, steel balls, wire segments, minerals and other abrasive centrifugal effect on the appearance of the steel jet treatment, not only can thoroughly remove rust, oxides and dirt , And the steel tube in the abrasive under the effect of fierce impact and friction, but also to achieve the desired average roughness.

3, tool rust. The use of wire brush and other tools on the polished steel surface, you can remove loose or tilt the oxide skin, rust, welding slag and so on. Rust removal of hand tools can reach Sa2 level, power tool rust can reach Sa3 level, if the appearance of steel attached strong oxide scale, the results of the tool rust is not satisfactory, reaching the depth of anchor embossed construction requirements.