Method of derusting spiral welded pipe

来源:www.spiralweldedtubemill.com 发表时间:2017-10-16

First, pickled rust

Generally used in two ways to do pickling treatment, respectively, chemical and electrolysis. Pipeline preservative only need to use chemical pickling, you can remove the oxide, the old coating, rust, and sometimes can be used as blasting after rust treatment. Chemical cleaning, although the surface can achieve a certain degree of cleanliness and roughness, but the anchor is shallow, and easy to cause pollution to the environment. In the case of

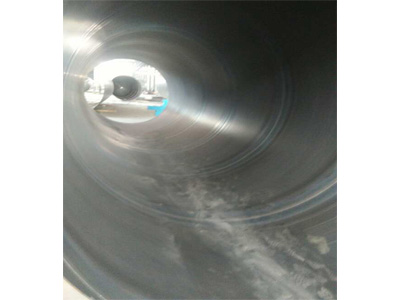

Second, spray (throw) shot rust

This kind of derusting method is through the high-power motor to drive spray (throw) to shoot the high-speed rotation of the blade, so that steel shot, wire section, grit, minerals and other abrasives under the action of centrifugal force on the surface of the pipe spray (throw) Can completely remove the rust, oxides and dirt, and the steel pipe in the abrasive impact and friction under the effect of, but also to achieve the required uniform roughness. In the case of

Spray (throw) after the rust, not only can expand the physical adsorption of the role of the tube, but also enhance the coating and the pipe surface of the mechanical adhesion. Therefore, the spray (throw) shot rust is the ideal way to rust pipe repair. In general, shot peening (sand) derusting is mainly used for tube surface treatment, shot blasting (sand) derusting is mainly used for pipe surface treatment. In the case of

The use of spray (throw) radiation rust should pay attention to several issues:

◆ rust level, commonly used for steel pipe epoxy, vinyl, phenolic and other anti-corrosion coating construction process, the general requirements of the steel surface to near white (Sa2.5). Practice has proved that the use of this rust level can almost remove all of the oxide, rust and other dirt, the depth of the anchor to reach 40 ~ 100μm, and fully meet the coating and steel pipe adhesion requirements, and spray (throw) The rust process can be achieved with lower operating costs and stable and reliable quality to near-white (Sa2.5) technical conditions. In the case of

Spray (throw) shot abrasive

◆ should be based on the hardness of the surface of the steel pipe, the original degree of corrosion, the required surface roughness, coating type to select the abrasive, for single-layer epoxy, two or three polyethylene coating, the use of steel sand and steel pills Abrasive easier to achieve the desired rust effect. Steel balls have the effect of reinforcing the steel surface, while the grit has the effect of etching the surface of the steel. Steel sand and steel shot of the mixed abrasive (usually steel balls hardness of 40 ~ 50 HRC, grit hardness of 50 ~ 60 HRC can be used for a variety of steel surface, even in the C and D grade corrosion steel surface , Rust effect is also very good.