Quality of spiral steel pipe

来源:www.spiralweldedtubemill.com 发表时间:2017-07-28

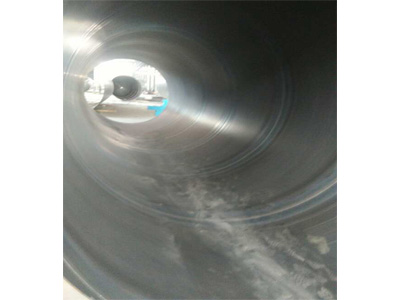

Spiral steel pipe equipment on the spiral pipe on-site solderability of the introduction:

Spot weldability is mainly determined by the raw material and port scale of the steel pipe. Taking into account the request of the construction of steel pipe, steel pipe processing and the connection of the shape of the scale of the consistency is particularly important.

The production of the spiral steel pipe is a continuous process which is basically stable under the same working conditions: the straight seam welding operation is segmented, including the whole plate / indenter / pre-roll / spot welding / welding / finishing / group pair Multi-channel process. This is an important feature of the production of spiral steel pipe in the production of straight seam welded pipe.

Stable production conditions are very easy to handle the quality of welding control and the scale of the guarantee. Because the spiral pipe equipment tube type regular, evenly distributed weld, relative to the straight seam welded pipe, spiral steel pipe has a very good oval and nose straightness, to ensure that the field of steel pipe group on the group when the accuracy.

The quality of spiral steel pipe equipment to determine the tips:

1, row square quality. Good stainless steel pipe unit industrial pipe row square, usually the surface showing a bright surface. Giving the impression of a bright spot.

2, steel pipe equipment components. Spiral steel pipe equipment components on the stability of the production of stainless steel will have a certain impact, without excluding some manufacturers in order to save money to cut corners and cement instead of real material.

3, the life of steel pipe equipment. With the quality of everyone to improve, product quality is a consumer demand for the purchase of important points. Small to day supplies, consumers are strictly requested quality problems. Not to mention the stainless steel pipe unit of this large investment equipment.