The important role of the spiral tube

来源:www.spiralweldedtubemill.com 发表时间:2017-07-28

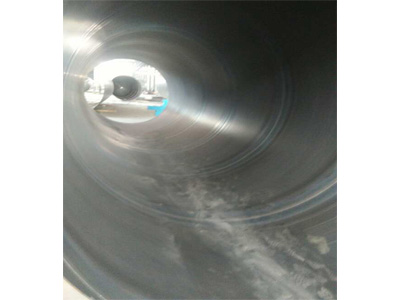

Many modern machines have the application of spiral pipe production equipment, it is precisely because it was only highlight the important role of the welded pipe unit. Whether it is in the car or in the ship has a large number of applications, especially in Germany and China cooperation in the production of this major case, fully illustrates the important role of spiral pipe production equipment.

From the structural point of view of the spiral pipe production equipment is low carbon structural steel or low alloy structural steel strip according to a certain helix angle rolled into the tube, and then welded joints welded together. In the production can be used in the production of narrow strip of large diameter steel pipe, the general type of such welded pipe units are used in oil and natural gas pipeline. The process is generally: open book, roll, leveling, butt welding, milling, forming, welding, welding, pipe, broken, follow-up welding, water pressure test and other major processes. This process also fully demonstrates the reliability and importance of spiral pipe production equipment in processing. Tianxiang Hao metallurgical equipment company to ensure the quality of the production of welded pipe unit is guaranteed, such as steel pipe diameter, wall thickness, oval, bending degree, tube-side vertical degree, the chemical have been hydrostatic test, acid corrosion test, Non-destructive testing and many other tests. These are the basis for ensuring the qualified performance of the welding unit.