Introduction of spiral welded pipe

来源:www.spiralweldedtubemill.com 发表时间:2017-08-18

Introduction

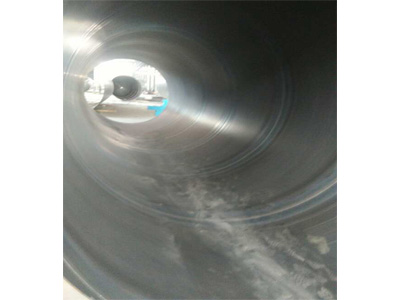

Definition: Equipment used to produce spiral welded pipe. Can produce narrower billets larger pipe diameter, but also can use the same width of the blank production pipe diameter different pipe.

Category: According to the molding angle adjustment method can be divided into: before the pendulum, rear pendulum;

According to the molding machine can be divided into different ways: on the volume, the next volume; (now under the volume is more commonly used, the volume is only used in a special case)

According to the forming method of the molding machine can be divided into: the next roll roll bed forming machine, sliding friction full sleeve molding machine, set roll joint molding machine, rolling friction full roll forming machine and the United States PRD company invented the continuous adjustment of production Diameter PRD molding machine. (Now the domestic general is rolling friction full roll forming machine)

Production Process:

Uncoiler → Unloading → Clipping Straightening → Shear Butt Welding / Cutting Butt Welding → (Disc Cut + Waste Edge Coiling) / Milling Machine → Delivery → Pre-Bend & Guide → Molding → Internal Welding → External Welding → Ruler cutting → out of the pipe → finished product collection