Spiral welded pipe national standard

来源:www.spiralweldedtubemill.com 发表时间:2017-09-07

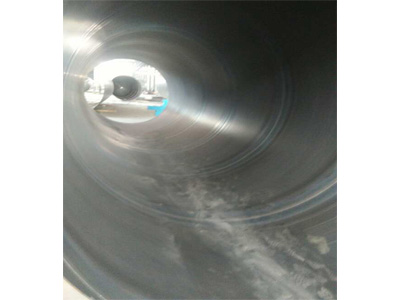

A Brief Introduction to Commonly Used National Specifications for Spiral Welded Pipe Equipment

specification

Spiral welded pipe equipment commonly used norms are generally divided into: SY / T5037-2000 (part of the standard, also known as the general fluid transport pipeline with spiral seam submerged arc welded steel pipe), GB / T9711.1-1997 (GB, also known as oil and gas industry transport (API), API-5L (American Petroleum Institute, also known as pipeline steel pipe; during which is divided into PSL1 and PSL2 two grades), API-5L (American Petroleum Institute, also known as pipeline steel pipe; SY / T5040-92 (Pile with spiral submerged arc welded steel pipe).

classification

Pressure pipe with spiral submerged arc welding pipe is mainly used for the transport of oil and natural gas pipeline, steel pipe pressure capacity, good plasticity, easy welding and processing molding; general low-pressure fluid transport with spiral submerged arc welded steel pipe double-sided active Submerged arc welding or single-sided welding made of water, gas, air and steam and other general low-pressure fluid transport with submerged arc welded pipe.

4 Features spiral welded pipe equipment features: Longitudinal seam welded pipe production process is simple, high production efficiency, low cost, carry out faster. The strength of the spiral welded pipe is generally higher than that of the straight seam welded pipe, and the pipe with larger diameter can be produced with the narrow billet, and the pipe with different diameter can be produced with the same width. But with the same length of the straight pipe compared to the length of the weld to add 30 to 100%, and the production rate is low. Thus, the smaller diameter of the pipe are mostly used straight seam welding, large diameter welded pipe is mostly used spiral welding.

5 raw materials commonly used in domestic spiral pipe raw materials are generally: Q235A, Q235B, Q345, L245, L290, X42, X52, X60, X70, X80, 0Cr13,1Cr17,00Cr19Ni11,1Cr18Ni9,0Cr18Ni11Nb.

Spiral welded pipe equipment storage on the surrounding environment requires a higher, if the preservation will cause corrosion of the pipe, adhere to the storage site clean and tidy, the environment is not contaminated. Some of the weeds or debris should be timely finishing. In the other side of the Treasury, but also pay attention to the warehouse clean and keep the information in the other process of clean. In order to avoid corrosion of the spiral pipe, do a good job before storage. Although the accumulation of the environment to do the best, but the spiral tube rust is inevitable, so the need for timely treatment of spiral welded pipe equipment, rust treatment.