Helpline viewpoints and components

来源:www.spiralweldedtubemill.com 发表时间:2017-10-25

The primary components of the screw steel pipe straightening machine include the structural components, the structural components, the roller assembly, the roller assembly, the gear reduction assembly and the various parts of the relationship.

In the spiral steel pipe machine straightening machine under the skin or billet, along the columnar direction of growth known as the bubble hole. Close to the surface of the supporting device Straightening machine slab, the spread of the relatively small bubbles is called the hole. According to the spiral welded pipe equipment straightening machine bubble position, exposed appearance, called the appearance of the bubble.

Shed bad foam is the main reason for the problem of spiral steel pipe equipment, but supporting equipment straightening machine contains a high amount of gas is also an important reason for the formation of foam. Together with the straightening machine in the process of casting the air, moisture will also occur bubbles. Shanxi spiral welded pipe equipment straightening machine appearance of the reasons for the formation of bubbles, usually in the condensation process of steel elements, such as oxygen, hydrogen, nitrogen and carbon concentration condensation interface. When it forms a CO, H2 and N2 gas, such as the total pressure is greater than the static pressure and the atmospheric pressure and the steel, there will be a bubble composition. If these bubbles can not quickly escape the steel, in Shanxi supporting equipment straightening machine slab appearance or subcutaneous there will be the existence of bubbles shortcomings. Continuous casting billet deoxidation often also occurs straightening machine billet appearance or subcutaneous bubbles. Other operations also have a certain impact on the shortcomings of the bubble, such as exercise, the end of the control is not correct, molten steel, hydrogen peroxide or tapping time is long, pouring temperature is high, in the ladle refractory baking, will add steel dissolved Gas, and lead to a series of bubbles.

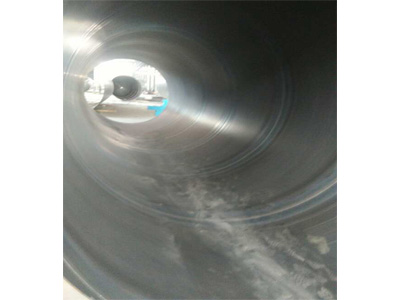

Spiral welded pipe equipment is low carbon carbon structural steel or low alloy structural steel strip according to the fixed spiral point of view into the tube billet, and then welded joints made, it can be produced with a narrow strip of large diameter Of the steel pipe, spiral welded pipe is mainly used for oil and natural gas pipeline, the standard with the outer wall thickness indicates that the spiral welded pipe equipment with single-sided welding and double-sided welding, welded pipe should ensure that the water pressure test, Strength and cold bending performance to meet the requirements.

And when the spiral welded pipe equipment explodes, because the weld is subjected to the normal stress and composition stress is relatively small, the explosion mouth generally does not originate from the spiral welded pipe equipment, its safety is higher than the straight seam welded pipe, because the radial stress is present in The maximum stress on the pipe, so the weld is in the direction of straight stress to accept the maximum load. That is, the maximum load received by the straight seam. The circumferential welds receive the smallest load, and the spiral joints are between the two. Spiral steel pipe welding seam spiral angle is generally 50-75 degrees, so the composition of the spiral weld stress is a straight seam welded pipe main stress of 60-85%.

At the same working pressure, the same pipe diameter spiral pipe than the straight seam welded pipe wall thickness can be reduced. Spiral steel pipe equipment according to the cross-sectional area of the shape can be divided into tube and shaped tube. Because in the circumference of the flat conditions, the largest circular area, with a circular tube to transport more fluid. In addition, the circular cross-section in the internal or external radial pressure, the force is more uniform, so the vast majority of steel pipe is a tube. According to the experiment, it is verified that the flexural pressure and the explosive pressure of the spiral welded pipe and the straight seam welded pipe are in good agreement with the theoretical value. However, both the pressure and the explosive pressure are lower than those of the straight seam welded pipe.The explosion test also shows that the annular deformation rate of the spiral welded pipe is significantly larger than that of the straight seam welded pipe, which proves that the plastic deformation capacity of the spiral welded pipe Better than the straight seam welded pipe, the explosion port is generally confined to a pitch, which is spiral welded pipe welding equipment on the expansion of the gap played a strong constraint caused by the effect. When the spiral welded pipe equipment adjacent to the existence of parallel with the shortcomings, because the spiral weld force is small, so the risk of expansion is not as good as straight seam. Spiral pipe fittings Many pipes used to transport fluids, such as pipelines for the transportation of oil, natural gas, gas, water and certain solid materials. Steel and round steel and other solid steel compared to the bending strength in the tonic strength together, the lighter weight, is an economic section of steel.